1.1 General

This test is applicable to enamelled round wire.

Resistance to refrigerant is expressed by the quantity of matter extracted from the coating of

the wire and by the breakdown voltage after exposure to a refrigerant.

NOTE 1 The data in this test method apply to monochlorodifluoromethane (refrigerant R 22). Other refrigerants

that have been determined by investigation to be appropriate for this test are provided in Annex A. When these

other refrigerants are used, it is important for safety reasons to observe the critical data for these refrigerants and

to comply with the revised test conditions during operation of the pressure vessel.

NOTE 2 Refrigerants like monochlorodifluoromethane and rinsing fluids like trichlorotrifluorethane (refrigerant

R 1 1 3) are ozone depleting chemicals (ODC). Refrigerant and rinsing fluid are agreed upon between customer and

supplier.

1.2 Extraction

1.2.1 Principle

A siphon cup containing the wire sample is placed in the pressure vessel. The extractable

matter is determined after exposure of the wire sample to the refrigerant under pressure and

at elevated temperature.

1.2.2 Equipment

The following equipment shall be used:

- siphon cup according to Figure 2, of 450 ml volume up to the siphoning level;

- pressure vessel of 2 000 ml volume with an internal diameter of approximately 1 00 mm

and a pressure capacity of 200 bar (20 MPa), preferably of unwelded construction and

provided with a controlled heating system;

- top closure of the vessel containing a condenser coil according to Figure 3;

- oven with forced air circulation.

Key

Height of cup: (82 ± 5) mm

Diameter of cup: (84 ± 5) mm

Diameter of tubing: (5 ± 1 ) mm

Figure 2 – Refrigerant extractable test siphon cup

1.2.3 Specimen

Eight wire samples each containing (0,6 ± 0,1 ) g of insulation shall be wound into coils of

70 turns. The specimens shall be degreased and conditioned in an oven with forced air

circulation at (1 50 ± 3) °C for 1 5 min. After 30 min cooling, the eight specimens shall be

weighed together to the nearest 0,000 1 g, resulting in the total initial mass M1 .

1.2.4 Procedure

The eight specimens shall be placed in the siphon cup, which is suspended (25 ± 5) mm

below the condenser coil on the pressure vessel cover. The pressure vessel shall be

assembled and charged with (700 ± 25) g of distilled refrigerant free from lubricant. The

condenser water supply and drain line shall be connected and the pressure vessel shall be

heated by means of a controlled heating system with the temperature set to (75 ± 5) °C or a

lower temperature if required to comply with the conditions of the following paragraph relating

to critical pressure. The water flowing through the condenser shall be adjusted to maintain a

reflux rate of 20 to 25 discharges per hour from the siphon cup. The extraction period shall be

6 h

The pressure in the vessel shall not exceed 75 % of the critical pressure of the refrigerant

chosen. Therefore, prior to use, the over-pressure control valve shall be checked to ensure its

proper functioning. The heating system should be automatically deactivated if the pressure

exceeds 75 % of the critical pressure of the refrigerant chosen or if the water flow through the

condenser coil is interrupted.

At the end of the extraction period the pressure vessel shall be cooled. The refrigerant shall

be removed from the pressure vessel and recovered using suitable means such as a

refrigerant compressor and recovery system. The pressure shall be released and the pressure

vessel opened.

For the following operations, the rinsing fluid shall be distilled before use.

The specimens and siphon cup shall be rinsed with the agreed rinsing fluid, the rinse poured

into the pressure vessel and the walls of the pressure vessel washed with two successive

rinses each of 1 00 ml of rinsing fluid. The fluid shall then be evaporated to (5 ± 1 ) mm from

the bottom of the pressure vessel and recovered in a safe manner.

The liquid sample shall be transferred to a pre-dried tared aluminium weighing dish and the

pressure vessel rinsed with 1 5 ml of rinsing fluid, which is transferred to the dish and then

evaporated to dryness at (1 50 ± 3) °C for (60 to 65) min. The weighing dish shall then be

cooled to room temperature in a desiccator. The dish with the residue shall be weighed to the

nearest 0,000 1 g and the original tared mass of the same dish subtracted. The difference is

the total residue mass M 2 of the matter extracted from the eight specimens.

The insulation on the coils shall be removed by suitable chemical means not affecting the

conductor and the bare conductors shall be dried at (1 50 ± 3) °C for (1 5 ± 1 ) min and cooled

to room temperature in a desiccator. They shall be weighed to the nearest 0,000 1 g and the

mass of the eight conductors together is the total conductor mass M 3 .

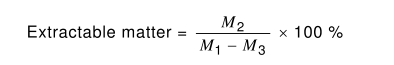

1.2.5 Result

The extractable matter shall be determined according to the following equation :

One test shall be made. The masses M 1 , M 2 , M 3 , the refrigerant, rinsing fluid, temperature,

pressure of the pressure vessel and the percentage extractable matter shall be reported.

1.3 Breakdown voltage

1.3.1 Principle

A specimen prepared according to 4.4.1 of IEC 60851 -5:2008 is placed in a pressure vessel according to 4.3.2. The breakdown voltage is determined after exposure of the specimen to the refrigerant under pressure and at elevated temperature.

1.3.2 Procedure

The specimen shall be conditioned in the oven (1 50 ± 3) °C for 4 h and then placed in the pressure vessel, which shall be assembled and charged with (1 400 ± 50) g of refrigerant. The pressure vessel shall be heated according to 4.2.4 but for a period of (72 ± 1 ) h.

At the end of the exposure period, the pressure vessel shall be cooled and discharged as described under 4.2.4. When the pressure inside the tube is less than 2 bar (0,2 MPa) absolute, the pressure vessel shall be opened and the specimen, within a period of 25 s to 30 s, transferred to the oven at a temperature of (1 50 ± 3) °C. The specimen shall remain in the oven for (1 0 ± 1 ) min. After the specimen is removed from the oven and allowed to cool to room temperature, the breakdown voltage shall be determined according to 4.4.1 of IEC 60851 -5:2008.

1.3.3 Result

Five specimens shall be tested. The five individual values shall be reported.