1.1 General

This test is applicable to enamelled round wire with a nominal conductor diameter over 0,250 mm and to enamelled rectangular wire.

The test is not suitable for round wires with a nominal conductor diameter up to and including 0,250 mm.

Resistance to solvents is expressed by the pencil hardness of the wire after solvent treatment.

1.2 Equipment

The following solvents shall be used:

- standard solvent as specified below, or

- solvent as agreed between purchaser and supplier.

The standard solvent shall be a mixture of:

- 60 % by volume white spirit with maximum aromatic content of 1 8 %;

- 30 % by volume xylene;

- 1 0 % by volume butanol.

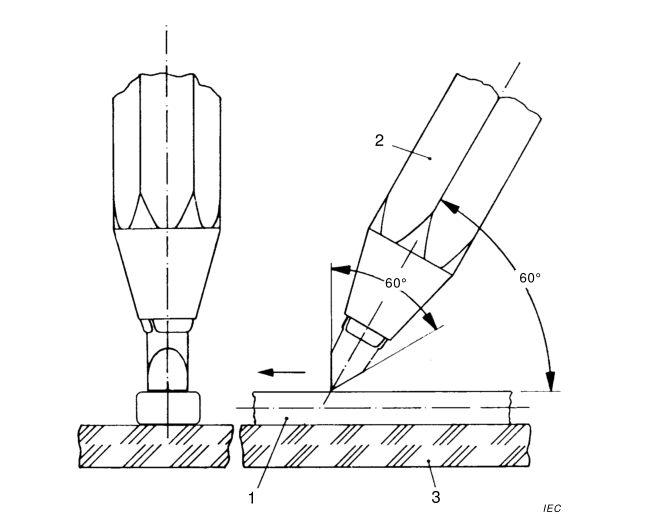

The pencil to be used shall be a lead pencil of the hardness specified in the relevant

standard. Before each test, the point of the pencil shall be sharpened with a smooth-cut file to

form an angle of 60° symmetrical about the axis of the lead according to Figure 1 .

Key

1 Winding wire specimen

2 Pencil

3 Test surface

NOTE Angle tolerances ±5°

Figure 1 – Pencil and specimen for solvent test

1.3 Procedure

A straight piece of wire, approximately 1 50 mm in length, shall be preconditioned for

(1 0 ± 1 ) min at (1 30 ± 3) °C in an oven with forced air circulation. A substantial length of the

wire shall then be immersed in standard solvent contained in a glass cylinder and shall be

maintained therein at a temperature of (60 ± 3) °C for a period of (30 ± 3) min. The wire shall then be removed from the solvent. The hardness of the wire surface shall then be determined

in the following manner within a period of 30 s after removal from the solvent.

The specimen to be tested shall be laid on a smooth hard surface according to Figure 1 . In

the case of rectangular wires, the test shall be carried out on the largest side of the wire. The

pencil shall be placed on the surface of the wire at an angle of approximately (60 ± 5) and the

sharpened edge shall be pressed slowly along the surface of the wire with a force of

approximately (5 ± 0,5) N.

Three tests shall be made. It shall be reported if the coating is removed with exposure of the

bare conductor.

NOTE 1 This method can also be used for testing resistance to other fluids, for example oil.

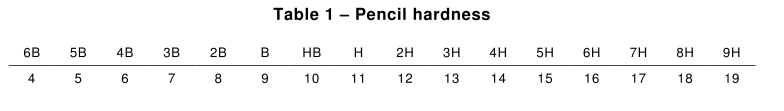

NOTE 2 Where it is desired to determine the hardness of the insulation, the hardness of the lead pencil which just

fails to remove the coating from the surface of the conductor is considered to be the hardness of the wire surface,

expressed by the pencil hardness. The pencil hardness series is as described in Table 1