For definitions, general notes on methods of test and the complete series of methods of test for winding wires, see IEC 60851-1.

The equipment used shall have a precision better than 2 µm. If a micrometer, which contacts the

wire, is used, it shall be ensured that the measuring force is in the range as given in table 1 . The

diameter range of the spindle and the anvil is also given in table 1 .

1 Scope

This part of IEC 60851 specifies the following method of test:

Test 4: Dimensions.

For definitions, general notes on methods of test and the complete series of methods of test

for winding wires, see IEC 60851-1.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60851-1, Winding wires – Test methods – Part 1: General

IEC 60851-5:2008, Winding wires – Test methods – Part 5: Electrical properties

3.1 Equipment

Round and rectangular wire

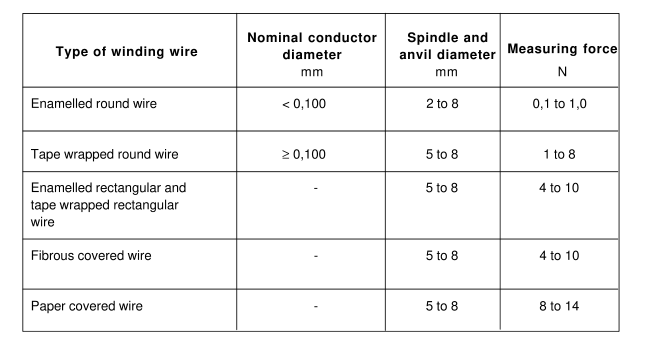

The equipment used shall have a precision better than 2 µm. If a micrometer, which contacts the

wire, is used, it shall be ensured that the measuring force is in the range as given in table 1 . The

diameter range of the spindle and the anvil is also given in table 1 .

3.1.2 Bunched wire

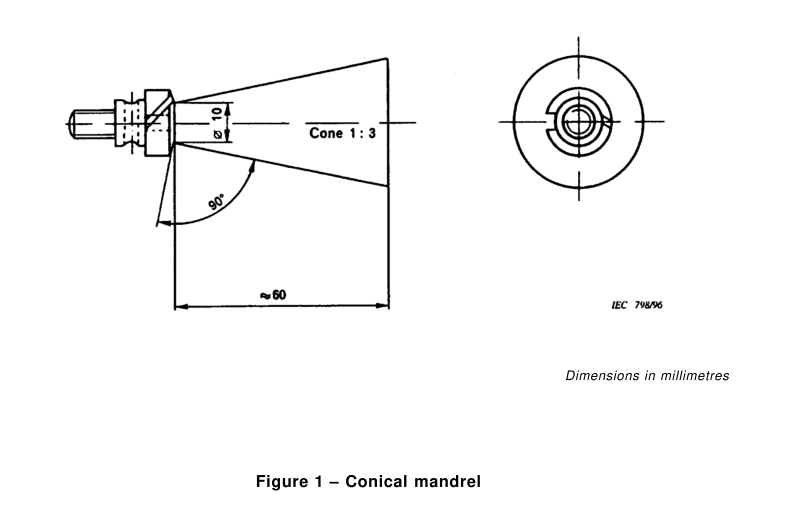

The measurement shall be made with a polished conical mandrel having dimensions as shown in

figure 1 .

3.2 Procedure

3.2.1 Conductor dimension

3.2.1.1 Round wire

NOTE – See table 2.

3.2.1.1.1 Nominal conductor diameter over 0,063 mm and up to and

including 0,200 mm

From a straight piece of wire the insulation shall be removed at three places, 1 m apart, by any

method that does not damage the conductor. One measurement shall be made at these three

places.

The three single values shall be reported. The mean value represents the conductor diameter.

3.2.1.1.2 Nominal conductor diameter over 0,200 mm

From a straight piece of wire, the insulation shall be removed by any method that does not

damage the conductor. Three measurements of the bare conductor diameter shall be made at

points evenly distributed around the circumference of the conductor.

The three single values shall be reported. The mean value represents the conductor diameter.

Type of winding wire

Nominal conductor

diameter

mm

Spindle and

anvil diameter

mm

Measuring force

N

Enamelled round wire< 0,1 00 2 to 8 0,1 to 1 ,0

Tape wrapped round wire ≥ 0,1 00 5 to 8 1 to 8

Enamelled rectangular and – 5 to 8 4 to 1 0

tape wrapped rectangular

wire

Fibrous covered wire- 5 to 84 to 1 0

Paper covered wire – 5 to 8 8 to 1 4

3.2.1.2 Rectangular wire

The insulation shall be removed at the three places used for measurements in 3.2.5.2 by any

method that does not damage the conductor. At each place one measurement of the two

dimensions of the conductor shall be made.

The three single values shall be reported for each dimension of the conductor. The mean

represents the conductor width or the conductor thickness respectively.

3.2.2 Out-of-roundness of the conductor

Out-of-roundness is the maximum value of the difference between any two readings of the

conductor diameter at each cross-section. The measurement shall be made in accordance

with 3.2.1 .1 .

The out-of-roundness shall be reported.

3.2.3 Rounding of corners of rectangular wire

For the purpose of this test, a cross-section of the wire shall be prepared and then examined under

a sufficient magnification.

Three straight pieces of wire shall be cast in a suitable resinous compound, that will not affect the

insulation. After curing, the colour of the resinous compound shall contrast with the colour of the

insulation.

The specimen consisting of the three pieces of wire embedded in the cured resinous compound

shall be cut at right angles to the length of the wire pieces and the cross-section shall be carefully

ground and polished by suitable means. The polished surface shall be examined under a

magnification which allows a correct judgement of the rounding of corners.

It shall be reported how the arc merges into the flat surface of the conductor. Any sharp, rough and

projecting edges shall also be reported.

3.2.4 Increase in dimension due to the insulation

The increase in dimension due to the insulation is the difference between the overall dimension

and the conductor dimension.

3.2.4.1 Round wire

The measurement shall be made in accordance with 3.2.1 .1 and 3.2.5.1 . The difference between

the overall diameter and the conductor diameter shall be reported as increase in diameter.

3.2.4.2 Rectangular wire

The measurement shall be made in accordance with 3.2.1 .2 and 3.2.5.2. The difference between

the overall width and the conductor width shall be reported as the increase in width. The difference

between the overall thickness and the conductor thickness shall be reported as increase in

thickness.

3.2.5 Overall dimension

3.2.5.1 Round wire

3.2.5.1.1 Nominal diameter up to and including 0,200 mm

On a straight piece of wire, at three places 1 m apart, one measurement of the overall diameter

shall be made.

The three single values shall be reported. The mean value represents the overall diameter.

3.2.5.1.2 Nominal conductor diameter over 0,200 mm

On a straight piece of wire, at each of two places 1 m apart, three measurements of the overall

diameter shall be made at points evenly distributed around the circumference of the wire.

The six single values shall be reported. The mean value represents the overall diameter.

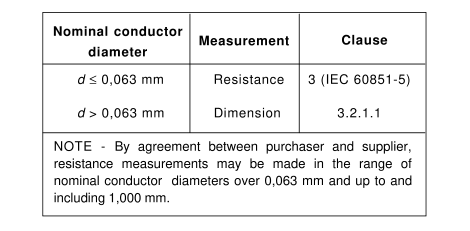

For determination of the conductor diameter as given in the relevant standards, the following

applies:

Table 2 – Determination of the conductor diameter

3.2.5.2 Rectangular wire

On a straight piece of wire at each of three places at least 1 00 mm apart, one measurement shall

be made of the two dimensions of the wire. Where the dimension of the specimen is greater than

the diameter of the micrometer spindle, measurements shall be made both at the centre of the

face of the specimen and over the edges. If these values differ, only the highest value shall be

noted.

The three single values shall be reported for each dimension of the wire. The mean values

represent the overall width or the overall thickness respectively.

3.2.5.3 Bunched wire

NOTE – The method indicated below gives useful values in practice, but not an accurate overall diameter.

The overall diameter is the width of a layer wound on a mandrel divided by the number of turns.

The bunched wire shall be wound closely on a mandrel according to figure 1 and under a tension

in newtons, which is 65 times the total nominal cross-section of the conductors in square

millimetres. The width of the layer shall be not less than 1 0 mm for bunched wires with overall

diameters up to and including 0,5 mm, and be not less than 20 mm for larger diameters and shall

be measured with a precision of 0,5 mm.

One measurement shall be made. The overall diameter rounded off to 0,01 mm shall be reported.

3.2.6 Increase in diameter due to the bonding layer of enamelled round wire

The increase in diameter due to the bonding layer is the difference of the overall diameter with and

without the bonding layer.

The overall diameter of the wire shall be measured according to 3.2.5.1 . After removal of the

bonding layer by means of a solvent or any other suitable agent or by any other method which

does not damage the underlying coating, the measurement shall be repeated. The difference of

the two mean values shall be reported as the increase in diameter due to the bonding layer.