p>After the insulating varnish is applied to the wire, the solvent and thinner are first evaporated in the baking process. Liquids turn into gases in two forms: evaporation and boiling. The molecules on the surface of the liquid enter the…

Baking process of enameled wire – curing

The wire enters the curing zone after passing through the evaporation zone, where the main chemical reaction of the paint occurs in the curing zone, that is, the cross-linking and curing of the paint base. For example, polyester paint is…

Baking process of enameled wire – waste

The solvent vapor and cracked low molecular substances generated during the baking process of the enameled wire must be discharged from the furnace in time. The density of the solvent vapor and the humidity in the gas will affect the…

Cooling process enameled wire

The enameled wire coming out of the oven has a high temperature, the paint film is very soft, and the strength is very small. If it is not cooled in time, the paint film of the guide wheel will be…

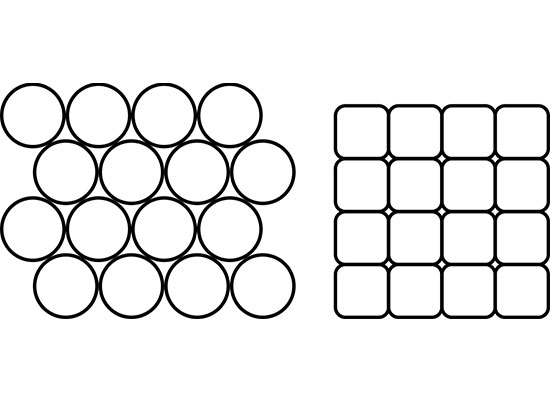

Round vs Square wire Design

Trends in Coil Winding call for custom construction, tight specifications and high-quality spooling. Electric car drive module benefits from square magnet wire Round vs Square wire Square magnet wire wire is useful where space constraints are concerned. When formed into…

Wire Drawing Of Enameled Wire

On a normal enameling machine, most of the operator’s energy and physical strength is consumed in the pay-off part. Replacing the pay-off reel makes the operator pay a lot of labor. When changing the wire, the joints are prone to…

Self-bonding enamelled wire

There are also special grades of enamel for specific applications. For example, there is “self-bonding” type of enamel which has an additional layer of adhesive. After a winding is made, the formed wires can be made to adhere to each…

Polyurethane (PU) enameled wire

Polyurethane (PU) enameled wire is an important variety in enameled wire products due to its direct solderability and hydrolysis resistance. The development of PU-enameled wire with a low friction coefficient is the guarantee of ultrahigh processing speed and the long…

Transformer winding

A transformer is an electrical device which, by the principles of electromagnetic induction, transfers electrical energy from one electric circuit to another, without changing the frequency. The energy transfer usually takes place with a change of voltage and current. Transformers…

Enamelled Copper Nickel Resistance Alloy Wire

Enamelled Copper Nickel Resistance Alloy Wires have been broadly used for standard resistors, automobile parts, winding resistors, etc. using the insulation processing best suited for these applications, taking full advantage of the distinctive features of enamel coating. Enamelled Copper Nickel…