Trends in Coil Winding call for custom construction, tight specifications and high-quality spooling.

Electric car drive module benefits from square magnet wire

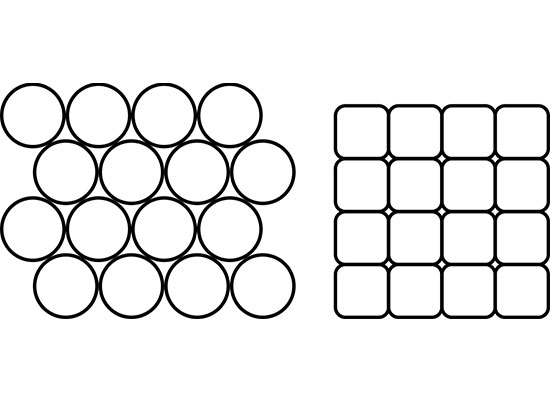

Round vs Square wire

Square magnet wire wire is useful where space constraints are concerned. When formed into a coil an equivalent amount of square wire put in a coil can be placed in a tighter coil configuration than the same amount of round wire. This enables engineers to create compact coils and small motors that deliver more power in less space. The opposite of this would be a random wire structure within the winding space, which is called “wild winding.”

For greater efficiency and reduced heat, dense packing of wires reduces air space and enables a higher fill factor. For best packing of round wires on a multi-layer winding, the wires in the upper layer are in the grooves of the lower layer for at least 300 degrees of the coil circumference. The wires occupy a dense package which is called “Orthocyclic winding”.