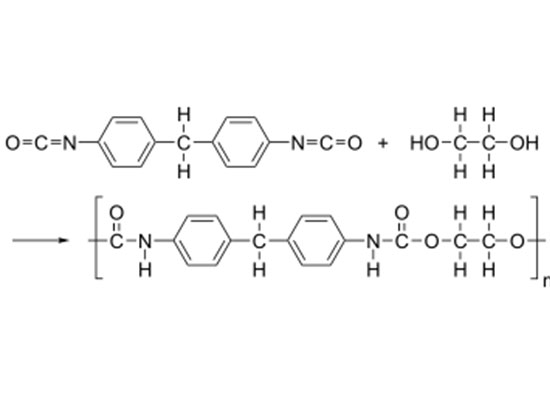

Polyurethane often abbreviated PUR and PU) refers to a class of polymers composed of organic units joined by carbamate (urethane) links. In contrast to other common polymers such as polyethylene and polystyrene, polyurethane is produced from a wide range of starting materials (monomers) and is therefore a class of polymers, rather than a distinct compound. This chemical variety allows for polyurethanes with very different physical properties, leading to an equally wide range of different applications. These include: rigid and flexible foams, varnishes and coatings, adhesives, electrical potting compounds, and fibres such as spandex and PUL. Of these, foams are the largest single application, accounting for 67% of all polyurethane produced in 2016.

Soft polyurethane is mainly a thermoplastic linear structure, which has better stability, chemical resistance, resilience and mechanical properties than PVC foam materials, and has less compression deformation. It has good thermal insulation, sound insulation, shock resistance and anti-virus performance. Therefore, it is used as packaging, sound insulation, filter material. [2] Rigid polyurethane plastic is light in weight, excellent in sound insulation and thermal insulation, chemical resistance, good electrical properties, easy processing, and low water absorption. It is mainly used in construction, automobile, aviation industry, thermal insulation structural materials. [2] The performance of polyurethane elastomer is between plastic and rubber, oil resistance, wear resistance, low temperature resistance, aging resistance, high hardness and elasticity. Mainly used in shoe industry and medical industry. Polyurethane can also be used to make adhesives, coatings, synthetic leather, etc.

HBU 336 S

Thermal Index: 130

Chemical Basis: Polyurethane

A polyurethane for general purpose, useful for application which needs less soldering residue but not so high thermal index. Wires made of it are fast soldering, and with very less residue. Good general performance, and pinhole resistant.

TONGSOLD 240

Thermal Index: 155

Chemical Basis: Polyurethane

This is a fast soldering polyurethane class 155 with equivalent other properties. Easy application, and with good pinhole resistance. The modified lower solid type shows faster soldering and less residue, better for fine wires. UL listed.

TONGSOLD 246

Thermal Index: 155

Chemical Basis: Polyurethane

This is a traditional polyurethane class 155 for general purpose, with excellent performance. Good runnability, excellent pinhole resistance according to JIS and good thermal properties. UL listed.

HBU 447 LS

Thermal Index: 155

Chemical Basis: Polyurethane

This is a polyurethane class 155 for general purpose, lower viscosity at higher solid, particularly used for fine wires, fast soldering with less soldering, and can be soldered at very low temperature. Good surface, and no dusting. Good general performances and pinhole resistant.

TONGSOLD 215

Thermal Index: 180

Chemical Basis: Polyurethane

This is a polyurethane class 155 for high speed application. Wires made of it are pinhole free according to JIS, good thermal properties such as higher cut-through. Solderable at 375℃. UL listed.

For detailed information, please contact technical service department: Xiaobing.Yu@altana.com

TONGSOLD 215 S

Thermal Index: 180

Chemical Basis: Polyurethane

This product is improved from Tongsold 215, with better pinhole resistance and heat shock. Wires made of it pass various tough tests for pinhole, including pinhole tests after elongation, rubbing and bending.

Polyurethane 1380

Thermal Index: 195

Chemical Basis: Polyurethane

This is a high thermal class polyurethane suitable for high enameling speed, excellent performance. Very good pinhole resistance and high thermal stability. Thermal index is high, but solderable at not so high temperature, and soldering fast. UL listed.

detail, visit https://en.wikipedia.org/wiki/Polyurethane,https://www.elantas.com/zhuhai/products-services/wire-enamels/polyurethane-enamels.html

| Primary applications/ special characteristics | Conductor diameter mm | Chemical base | Temperature index IEC 172 |

| Solderable magnet wires, pin-hole andcrazing resistant | 0,02 – 0,80 | Polyurethane | TI / 195 |

| Solderable magnet wires | 0,07 – 1,30 | Polyurethane | TI / 164 |

| Solderable magnet wires | 0,30 – 2,00 | Polyurethane | TI / 151 |

| Solderable magnet wires, soldering temperature > 320 °C | f0,02 – 0,60 | Polyurethane | TI / 168 |

| Top coat for solderable magnet wires containing a lubricant | 0,02 – 0,60 | Polyurethane modified | |

| Solderable magnet wires, pin-hole and crazing resistant | 0,02 – 1,30 | Polyurethane | TI / 210 |

| Solderable magnet wires, pin-hole and crazing resistant | 0,02 – 1,30 | Polyurethane | TI / 211 |