A class of polymers whose repeating units are characterized by ester groups and imide groups. It is usually obtained by imidization of polyester amic acid, and has the characteristics of high temperature resistance and good processability.

Polyesterimide PEI is extensively used wire enamel with excellent thermal properties, class 180 or above, both in single coating and in dual coating applications. Its wires are widely used for compressors, washing machine motors, explosion-proof motors, electric tools, ballasts and dry transformers etc.

Thermal Index:180, 200

Chemical Basis: THEIC-modified Polyesterimide

Properties and applications

Polyesterimides (PEI) are a class of high performance engineering thermoplastics or thermosets that combine the advantages of high temperature stability with ease of processing. In addition, these polymers offer excellent electrical properties such as very high dielectric strength and high overload resistance as well as superior mechanical properties such as good heat shock and stress cracking resistance and good windability.

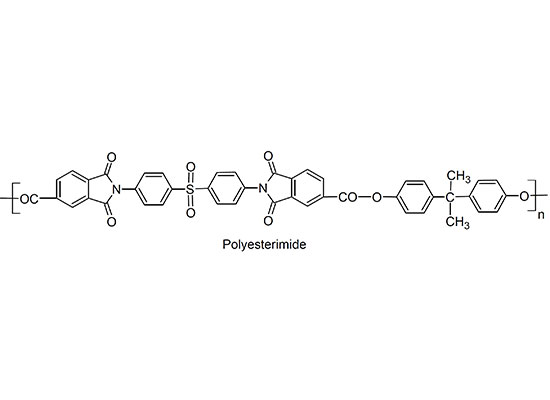

Polyesterimides can be prepared by condensation polymerization of an aromatic ether diamine (e.g. diaminodiphenyl sulfone, DADS) with an aromatic acid anhydride (e.g. trimellitic acid anhydride, TMA) and a diol/triol (e.g. bisphenol A and tris(hydoxyethyl isocyanurate, THEIC).2

The aromatic ring structure along the polymer backbone improves the thermal, mechanical, and chemical properties whereas the introduction of ester groups and flexible linkers improves melt processabiliy and toughness (impact strength). In some cases, double bonds are introduced in the polymer backbone which can serve as cross-linking sites. Some other PEIs contain unreacted functional groups. For example, (end-functional) hydroxyl groups can be crosslinked with phenolic resins.

(Crosslinkable) polyesterimides are widely used as wire enamels on magnet wires3 for motors, generators, relays, ignition coils, and transformers which are uses in a multitude of appliances, electrical tools, and industrial machines such as compressors, washing machines, explosion-proof motors, drilling machines, and automotive motors. The enamels provide electrical insulation and prevent the windings from short-circuiting. They also protect the coils against corrosion and thermal-oxidative degradation in demanding environments.

| Primary applications/ special characteristics | Conductor diameter mm | Chemical base | Temperature index IEC 172 |

| Overcoat | 0,02 – 1,80 | Polyamideimide | TI / 230 |

| Overcoat | 0,50 – 5,00 | Polyamideimide | TI / 240 |

| Overcoat 2 | 0,50 – 5,00 | Polyamideimide | TI / 232 |