The temperature at which a short-circuit current is generated between the samples for softening breakdown by making the two wire samples intersect vertically, and applying a specified load to the intersection point.

express.

NOTE: In many cases, the softening breakdown degree indicates the temperature at which the insulation breaks down.

4.1 Test equipment

The following test equipment should be used:

A brass or copper metal block. With electrical heating and temperature measurement and temperature control device, there are two jacks on it that can be inserted into the gold mesh block

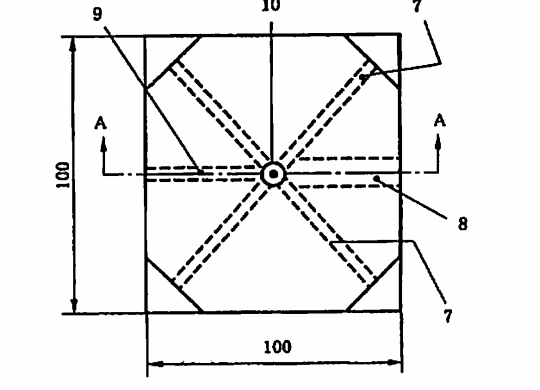

A test specimen with a vertical cross in the center, with a ceramic strut for applying a load at the point of intersection, as shown in Figure 1;

11. A transformer with a capacity of at least 100VA, capable of outputting an AC test voltage of (100±10)V, and operating when the current is (5±1)mA

An overcurrent device to be used, and a current-limiting resistor connection to limit the current to not exceed 50mA.

4.2 Test procedure

Insert two vertically intersecting straightening samples into the metal block preheated to the temperature specified in the relevant product standard. should be as close as possible to the intersection

Measure the temperature, and the measured value should be within the range of the specified value ± 3 °C. The intersection point should be centered under the strut. For conductors with nominal diameter less than

For the 0.200mm sample, insert the two samples into the jack in parallel, and place the third sample vertically on the first two samples, and the intersection points should be symmetrical

on the rod axis.

After the heating time specified in Table 2 is over, apply the load specified in Table 3 with the pressure rod, and then immediately apply the load between the upper and lower samples.

Test voltage. If below are two specimens placed in parallel, they should be connected to each other. The application time of load and test voltage shall be 2n.

Do three trials. The number of short circuits should be recorded.