The Felt Varinishing method has a simple structure and is easy to operate. As long as the felt splint is used to flatly clamp the felt on both sides of the wire, the felt is loose, soft, elastic and porous to form a die hole and scrape off excess on the wire. The lacquer absorbs, stores, transports and makes up the lacquer through the capillary phenomenon, and coats the surface of the wire with a uniform lacquer.

Felt Varinishing method is not suitable for enameled wire enamels with too fast solvent evaporation or too high viscosity. Too fast evaporation and too high viscosity will cause the pores of felt to be blocked and lose its good elasticity and capillary siphon ability quickly.

When using the felt painting method, you must pay attention to:

1) The distance between the felt clamp and the oven inlet. Consider the resultant effect between the leveling and gravity after painting, the factors of the sag and the gravity of the paint liquid when the line is traveling, the distance between the felt and the paint tank (horizontal machine) is 50-80mm, and the distance between the felt and the furnace mouth 200-250mm is appropriate.

2) Specifications of felt. When painting rough specifications, the felt is required to be wide, thick, soft, elastic, and have many capillary pores. The felt is easy to form relatively large die holes during painting, and the paint storage capacity is large and the paint is transported quickly. When coating thin lines, it is required to be narrow, thin, fine, and small capillary. Cotton cloth or undershirt cloth can be used to wrap the felt to form a fine and soft surface, so that the amount of paint is small and uniform.

Painted felt size and density requirements

Specification mm width × thickness density g/cm3 Specification mm width × thickness density g/cm3e

0.8~2.5 50×16 0.14~0.16 0.1~0.2 30×6 0.25~0.30

0.4~0.8 40×12 0.16~0.20 0.05~0.10 25×4 0.30~0.35

0.2~0.4 40×8 0.20~0.25 0.05 Below 20×3 0.35~0.40

3) The quality of the felt. Painting requires the use of high-quality wool felt with fine and long fibers (foreign countries have begun to use fully synthetic fibers with excellent heat resistance and wear resistance to replace wool felt). The fat content is less than 0.5%, the pH value is 7, and the thickness is uniform.

4) Requirements for felt plywood. The splint must be finely planed, not rusted, and maintain a flat contact surface with the felt, without bending or deformation. Depending on the diameter of the wire, prepare splints of different weights, try to control the tightness of the felt by the self-gravity of the splint, and avoid pressing with elastic screws or springs. The method of self-gravity compaction results in a fairly consistent paint finish from wire to wire.

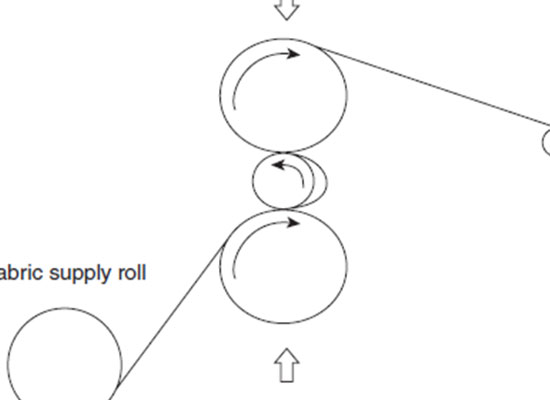

5) The felt and the paint supply should be well matched. When the paint remains unchanged, the amount of paint supply can be controlled by adjusting the number of revolutions of the paint delivery roller. The placement of the felt and splint with the wire should be such that the forming die hole is level with the wire to keep the felt pressure evenly around the wire. The horizontal position of the guide wheel of the horizontal enameling machine should be lower than the top of the paint roller, and the height of the top of the paint roller and the center of the felt interlayer must be on the same horizontal line. In order to ensure the paint film thickness and smoothness of the enameled wire, it is advisable to use a small cycle for paint supply, the paint liquid is pumped into the large paint box, and the circulating paint is pumped from the large paint box into the small paint tank. Replenish the small paint tank, so that the paint in the small paint tank maintains a uniform viscosity and solid content.

6) After a period of use of the painted felt, the capillary pores will be blocked by the copper powder on the copper wire or other impurities in the paint, and the broken wire, glued wire or joint during production will also scratch the soft and uniform surface of the felt. The surface of the wire is damaged by friction with the felt for a long time, and the temperature radiation at the furnace mouth makes the felt hardened, so it needs to be replaced regularly.

7) Felt painting has its inevitable disadvantages. Frequent replacement has low utilization rate, increased waste, and large felt loss; the thickness of the paint film between the lines is not easy to reach the same; it is easy to cause the eccentricity of the paint film; the speed of the vehicle is limited. When the wire speed is too fast, the friction caused by the relative movement between the wire and the felt will generate heat, change the viscosity of the paint, and even burn the felt; improper operation will bring the felt into the furnace to cause a fire accident; There is felt wire, which will have a bad effect on the enameled wire with high temperature resistance; high viscosity paint cannot be used, and the cost will increase.