The solvent vapor and cracked low molecular substances generated during the baking process of the enameled wire must be discharged from the furnace in time. The density of the solvent vapor and the humidity in the gas will affect the…

Cooling process enameled wire

The enameled wire coming out of the oven has a high temperature, the paint film is very soft, and the strength is very small. If it is not cooled in time, the paint film of the guide wheel will be…

Coils winding enameled wire

The purpose of winding and arranging the wire is to wind the enameled wire on the bobbin continuously, tightly and evenly. It is required that the wire take-up mechanism has a smooth transmission, low noise, proper tension and regular wire…

How to remove the enamel from wire?

For thick enameled wire, use a knife or a broken saw blade to scrape off the patent leather one by one. When scraping, do not only scrape both sides, but carefully scrape around the circle without scratching the wire. This…

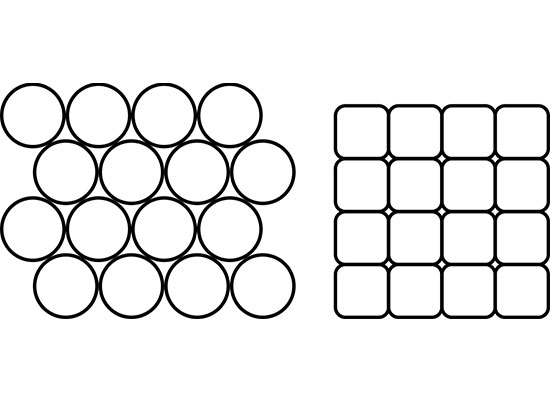

Round vs Square wire Design

Trends in Coil Winding call for custom construction, tight specifications and high-quality spooling. Electric car drive module benefits from square magnet wire Round vs Square wire Square magnet wire wire is useful where space constraints are concerned. When formed into…

Orthocyclic winding

Orthocyclic winding structure creates an optimal fill factor (90.7%) for round wires. The windings of the upper layer need to be placed into the grooves provided by the lower layer. Rectangular magnet wire used in Orthocyclic winding The best volume…

Wire Drawing Of Enameled Wire

On a normal enameling machine, most of the operator’s energy and physical strength is consumed in the pay-off part. Replacing the pay-off reel makes the operator pay a lot of labor. When changing the wire, the joints are prone to…

Three Wire Winding Geometries

Ideally, the winding should be positioned parallel to the winding flange, meeting an orthogonality condition. It is necessary to adjust the winding width to the number of turns per layer of the winding. For non-circular shaped coil cross-sectional areas, it…

Production process of enamelled wire

The production process involves several stages: drawing the wire – from a thicker gauge to the target diameter (in several steps) annealing – to remove mechanical stress coating – with raw enamel (liquid resin) curing – drying off the volatile…