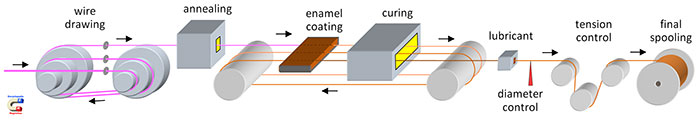

The production process involves several stages:

drawing the wire – from a thicker gauge to the target diameter (in several steps)

annealing – to remove mechanical stress

coating – with raw enamel (liquid resin)

curing – drying off the volatile content of the resin and forming the polymer links

applying lubricant – for easing further mechanical processing

quality control – checking the diameter of the manufacture wire

final spooling – on standardised reels, ready for shipping to the final user