- Why is it a flat wire?

- Miniaturization – high slot full rate, high power density

- Fast heat dissipation – large wire contact area and short heat dissipation path

- High reliability – ordered distribution

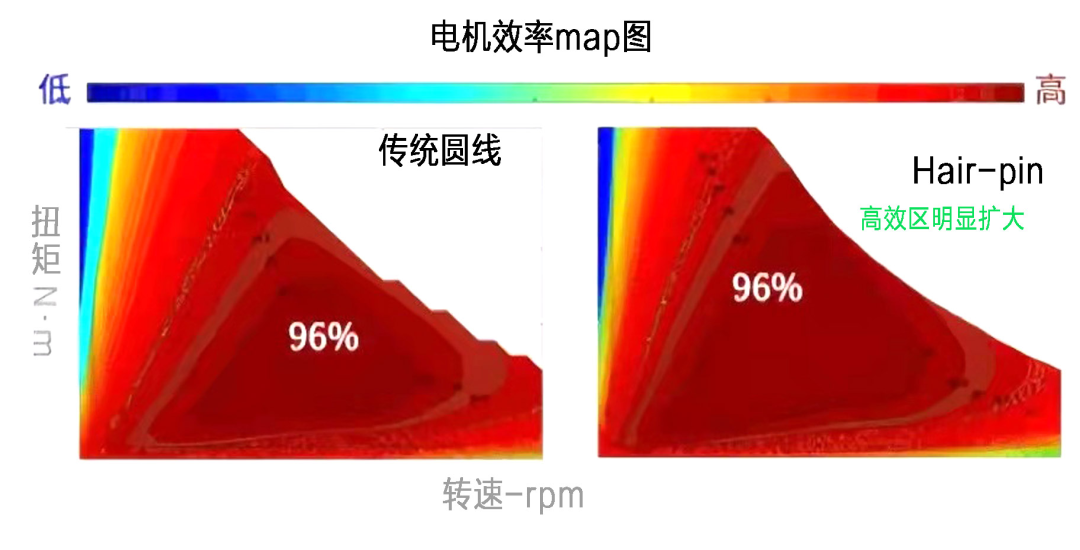

- The high-efficiency interval is larger than that of the round line

- Low NVH – high mechanical strength

Advantage 1: The same power, smaller volume, less material, lower cost, or the same volume, the slot full rate is increased, and the power density is increased. The round wire becomes a flat wire. In theory, under the premise of the same space, the flat wire motor can achieve a slot full rate of 70%, and the filled copper can be increased by 20-30%, resulting in a stronger magnetic field strength. In a way that equates to a 20-30% increase in power.

Advantage 2: Better temperature performance. The internal space is reduced, the contact area between the flat wire and the flat wire is large, and the heat dissipation and heat conduction are better; the contact between the winding and the iron core slot is better, the heat transfer path is shortened, and the heat conduction is better; the motor is very sensitive to heat dissipation and temperature Sensitive, better heat dissipation and better performance. Some people have simulated the temperature field and found that the temperature rise of the flat copper wire motor with the same design is 10% lower than that of the round copper wire motor.

The distribution of the flat wire in the slot is regular and orderly, and it is easy to avoid contact between the first and last turns. In the flat-wire stator windings of the same slot and the same phase, the input voltage is distributed over multiple turns in an orderly manner. According to the relevant literature, under the PWM pulse voltage, the inter-turn of the line-end winding bears a larger voltage stress than the inter-turn of other windings, but it is much lower than the input voltage. The voltage distribution between turns is directly related to the electromagnetic design of the motor. Taking the diagram as an example, if the electromagnetic design of the motor is not reasonable, the voltage difference between the two adjacent layers of wires at the bottom of the slot or the slot will be large, resulting in the need for Increasing the interlayer insulation reduces the slot full rate and reduces the motor performance.

Most of the round wire windings are inserted into the slot in a scattered way. The contact between turns is irregular, and the first and last turns are prone to contact. The designed insulation strength between turns must be consistent with the bus voltage.

- The history of flat wire for automotive motors

- Flat wire for automobile generator

- 48V hybrid

- HEV, EV low-voltage platform

- EV high voltage platform

- The changing trend of flat wire for vehicle drive motor

- Film thickness and breakdown voltage

- Eccentricity

- Coating properties

Fourth, the demand for technological progress

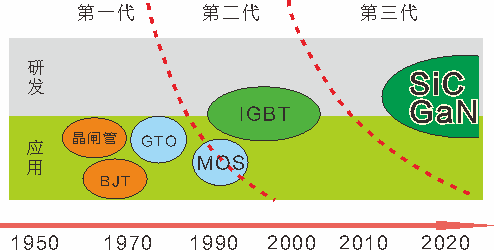

- Application of high-power devices in vehicle drive motor systems

- Si to SiC

- Introduction to PDIV test

- Introduction to corona resistance characteristics

- How to choose a reasonable corona resistance life index?

SiC MOSFET turn-on and turn-off time < 100 ns, resulting in higher overshoot voltage than Si IGBT

The frequency can be as high as 40KHz, and the frequency of the shock to the insulation rises.

According to data provided by some controller engineers, the overshoot voltage of SiC controllers can reach twice the operating voltage, which is higher than that of Si-based IGBTs.

Much of the PDIV data tested so far is based on a sine wave, whereas PWM modulates a high frequency square wave. Adopting the design of the type 1 insulation scheme specified by IEC, some engineers control the Vp value at 2 times the operating voltage. Some people think that the effective value should be used according to the definition of the standard. Another part of the design takes into account the influence of frequency, waveform, PDEV, high temperature, and aging, and continuously increases the value of PDIV at room temperature.

In the last report, it was mentioned that the choice of corona resistance life is an empirical value. With the in-depth understanding of the operating principle of the motor, the following assumptions are put forward to correspond to the corona resistance life, in order to attract more ideas.

Example:

Assuming that the motor speed is 15000rpm, 4 poles, and the output frequency of the controller is 20KHz, the maximum number of carriers N=20K/(15000*4/60)=20, which is converted according to the effective value of the sine wave, and the square wave high level time per minute = 1/1000/sqrt(2)*15000=10.5s

The top speed corresponding to a certain model’s 15000rpm speed is 189km/h.

Corona resistance time corresponding to 300,000 kilometers under extreme speed conditions

=300000/189*10.5/60=277.8h

(When the rising edge and overshoot voltage are determined, the number of carriers determines the choice of the corona resistance life index. The actual operating voltage of the IGBT output is lower than 800V, and the corona resistance life should be assessed according to the lower test voltage. For motors driven by SiC or GaN controllers, the output frequency and output voltage will be higher and longer test life is expected.)

Five, some future solutions

- Will you choose to go back to the round wire or the Ritz flat wire?

- Increase the aspect ratio

- Multilayer

- Cancellation of slot insulation

Due to the serious skin effect of high frequency, the flat wire motor has no efficiency advantage under extreme speed conditions, and there are already research institutions trying to make the force of the wire. However, most domestic vehicles are in low-speed conditions. If you simply use round wires or Ritz flat wires to improve high-speed performance, it will have a greater impact on the comprehensive endurance of the vehicle. The manufacturing cost of Ritz flat wires is higher, only in some cases. Advantages under certain conditions. From the above analysis, it can be seen that the enameled flat wire has been able to meet the stringent requirements of vehicle drive motor windings in all aspects, and the probability of large-scale application of enameled flat wire is the highest in the future. The flat wire itself still has more room for improvement.