This test method is applicable to the determination of the dielectric loss tangent (tand) of enameled round wires.

Measurements should be made at a frequency of about 1MHz.

This test method is also applicable to the determination of the dielectric loss tangent of enameled flat wire.

The provisions of this standard are consistent with the provisions of the International Electrotechnical Commission (IEC) 251-1 (1978) and (IEC) 251-3 (1978).

1 Test equipment

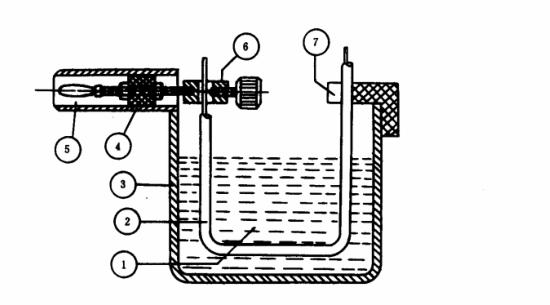

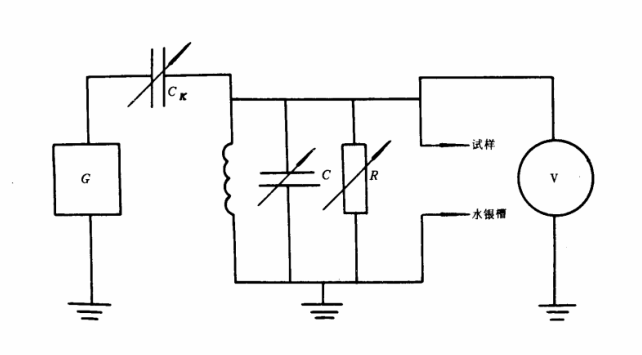

The wiring diagram of the test device is shown in Figure 1.

2 Sample preparation

Take an enameled wire with a length of about 300mm, wipe it with a soft cloth, and bend it into a “U” shape at a distance of about 100mm from both ends.

Method, scrape one end off about 25mm of paint film.

experiment procedure

3.1 Immerse the prepared “U”-shaped sample into the mercury tank, and adjust the depth of the sample immersed in the mercury tank to ensure that the sample and water

The capacitance between the silver grooves is between 50 and 100pF, and then the sample is fixed on the terminal and connected to the test device. as shown in picture 2.

3.2 Adjust the damping resistance to infinity, and use the capacitor C to adjust the reading of the voltmeter in the circuit to the maximum.

3.3 With the coupling capacitor, adjust the reading of the voltmeter V to the predetermined value, and record the value C1 of the capacitor at this time.

3.4 Disconnect the sample, use the capacitor to adjust the circuit again, and record the value C20 of the capacitor C at this time

3.5

Use the resistance reset to the previous value of the voltmeter reading, and note the value Ry of the resistor R at this time.

3.6 The measurement accuracy should reach ±10%.