This test method is suitable for determining the breakdown voltage resistance of the paint film of enameled flat wire under normal or high temperature conditions.

The provisions of this standard are consistent with the provisions of the International Electrotechnical Commission (IEC) 251-3 (1978).

1 Test equipment

1.1

The main components of the breakdown voltage test bench shall meet the following requirements.

1.1.1 Test transformer

Rated capacity: >500VA

Output waveform: approximate sine wave

Output current: >5mA

Maximum pressure drop: 2%

1.1.2i

Test voltage

Frequency: 50Hz or 60Hz

Waveform: Approximate sine wave

Bee value coefficient: √2±5%(1.34~1.48)

1.1.3

When the action current of the high-voltage circuit current relay is equal to or greater than 5mA, it can cut off the power supply and indicate the breakdown.

1.2

The surface of the test bar is polished.

1.8

The diameter of the electrode steel ball is not more than 2mm, and it should be cleaned with appropriate solvent regularly to prevent rust.

1.4 Electric heating blast box 0~300℃.

2 Sample preparation

2.1 The length of the sample is 350mm, and 5 samples should be sampled for each test of ancestry conditions.

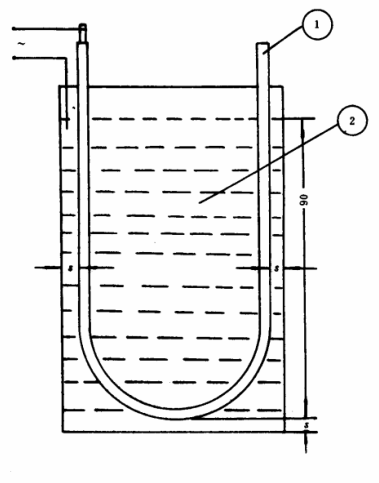

2.2 Remove the insulation from one end of the specimen. On the test rod of the diameter specified in Table 1, bend the broad side of the test piece to form a “U” shape.

3 test steps

3.1 Room temperature test

3.1.1 According to the regulations in the figure, place the sample in the electrode tank filled with beads, and the two ends of the sample must protrude for a considerable length.

3.1.2 Between the steel ball and the sample conductor, apply a voltage at the boosting speed specified in Table 2 until it breaks down.

3.1.3

The test can also be performed in a cuff-filled electrode tank. The type of sleeve and the breakdown voltage value are determined by the manufacturer and the user through negotiation.

3.2 High temperature test

3.2.1 Put the steel ball and electrode tank into the electric heating blast box, and preheat to the temperature specified in the product standard.

3.2.2 Put the U-shaped sample into the electrode tank as specified in the figure, and heat it to the specified temperature.

8.2.3

Within 15 minutes after the sample reaches the specified temperature, the test shall be carried out according to the provisions of Section 4.1.2.

3.2.4

The total time of the sample in the electric blast box should not exceed 30mn.

4 Test results and calculations

The breakdown voltage values of the 5 samples measured at room temperature or high temperature must meet the requirements of the product standard.