Lacquered wire (magnetic wire) is one of the main types of winding wire. It is composed of conductor and insulating layer. The bare wire is softened by annealing, then painted for many times and baked. Enameled wire spool is important as a device for receiving coils after enameled wire is finished.

According to the spool shape can be divided into: double conical, round bucket type, conical, line storage bucket.

Double conical spool is suitable for storing fine and very fine enameled wire. It is suitable for copper wire. The wire diameter is 0.01 to 0.15mm.

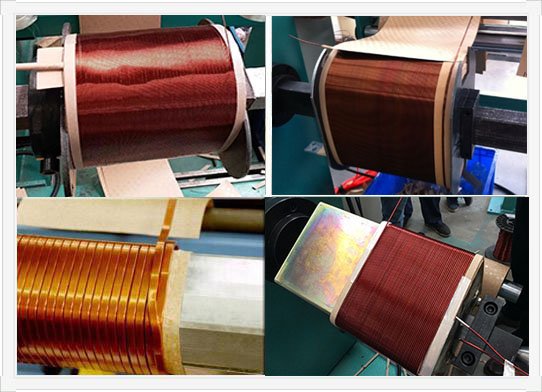

Cylindrical bobbin is the mainstream of winding bobbin, suitable for copper and aluminum wire, wire diameter of about 0.05-0.5mm, this traditional design has been favored by customers for its robustness.

Conical spool is suitable for storing thick enameled wire, suitable for copper wire, its wire diameter size is 0.1 to 0.5mm, winding ability is stable.

Line storage bucket spool sizes ranging from 400 to 700mm, these are specially designed storage containers for large magnetic wires. The enveloped design provides the best protection for large coils and is suitable for any large magnetic wire.

According to the material of the spool can be divided into: wood, plastic, paper and steel.

Wooden spool: The use of multilayer plywood made of both sides of the side plate, according to the use and requirements of different levels of kraft paper tube core, waterproof and bearing capacity is large, the maximum bearing capacity of the tube core is 3 tons, metal combination, in recent years, the application of wood wire coil is more and more widely, the original ecological wood packaging products are far greater than plastic products. No odor, no fumigation. Flexible specifications, any size can be produced, the price has considerable advantages. If we must sum up a shortcoming, it is the production efficiency is not high, the production cycle is slightly longer.