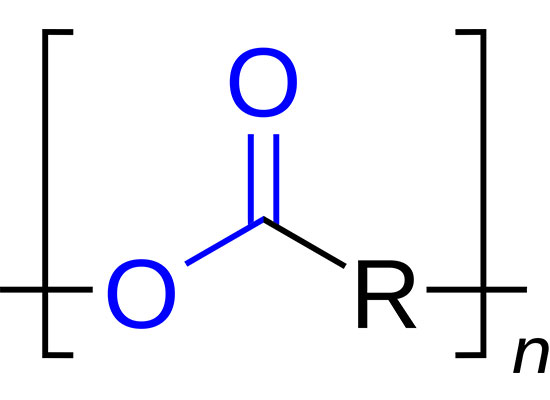

Polyester is a category of polymers that contain the ester functional group in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include naturally occurring chemicals, such as in plants and insects, as well as synthetics such as polybutyrate. Natural polyesters and a few synthetic ones are biodegradable, but most synthetic polyesters are not. Synthetic polyesters are used extensively in clothing.

Polyesters are one used to make bottles, films, tarpaulin, sails (Dacron), canoes, liquid crystal displays, holograms, filters, dielectric film for capacitors, film insulation for wire and insulating tapes. Polyesters are widely used as a finish on high-quality wood products such as guitars, pianos, and vehicle/yacht interiors. Thixotropic properties of spray-applicable polyesters make them ideal for use on open-grain timbers, as they can quickly fill wood grain, with a high-build film thickness per coat. It can be used for fashionable dresses, but it is most admired for its ability to resist wrinkling and shrinking while washing the product. Its toughness makes it a frequent choice for children’s wear. Polyester is often blended with other fibres like cotton to get the best of both worlds. Cured polyesters can be sanded and polished to a high-gloss, durable finish.

Polyethylene terephthalate, the polyester with the greatest market share, is a synthetic polymer made of purified terephthalic acid (PTA) or its dimethyl ester dimethyl terephthalate (DMT) and monoethylene glycol (MEG).

Polyester Enamels is composed mainly of polyester, available in various thermal classes with good overall properties. Used in motors, instrumets and tools etc. THEIC-modified type is also used for compressor wires.

Thermal Index: 130

Chemical Basis: Terephthalic Polyester

This is a terephthalic polyester wire enamel, belonging to plain polyester class 130 for general purpose. Low viscosity and high solid content, suitable for high speed enameling by felt, with smooth surface, good adhesion and dielectric properties.

Thermal Index: 130

Chemical Basis: Terephthalic Polyester

This is a specially designed plain polyester wire enamel class 130. Suitable for enameling rectangular copper wires, excellent mechanical properties and edge cover uniformity property.

Thermal Index: –

Chemical Basis: Modified Polyester

Suitable for various machines, easy application, good gloss. With excellent flexibility and adhesion, excellent pinhole resistance. Used in the manufacturing of plain polyester wires or its dual coating wires. For motors, electric devices, tools and toys etc.

Thermal Index: 155

Chemical Basis: Modified Polyester

This is a modified polyester, with general performance of polyesters, and specially designed for pinhole free. Excellent pinhole resistance in salty water. Satisfy requirement of pinhole free even after elongation, rubbing and bending.

Thermal Index: 180

Chemical Basis: THEIC-modified Polyester

This is a THEIC modified polyester enamel with good performance, for general purpose. Suitable for various machines, easy enameling, with good adhesion. UL listed.

Thermal Index: 203

Chemical Basis: THEIC-modified Polyester

THEIC modified polyester enamel for general purpose, improved for high speed machines. Excellent flexibility, adhesion, and Techrand windability. Some properties kept at high level even after aging, such as STP. UL listed.

Thermal Index: 180

Chemical Basis: THEIC-modified Polyester

This is a THEIC modified polyester enamel with good flexibility, better for large round wires or rectangular wires, also suitable for general purpose. Used on various machines, easy enameling and good performance.