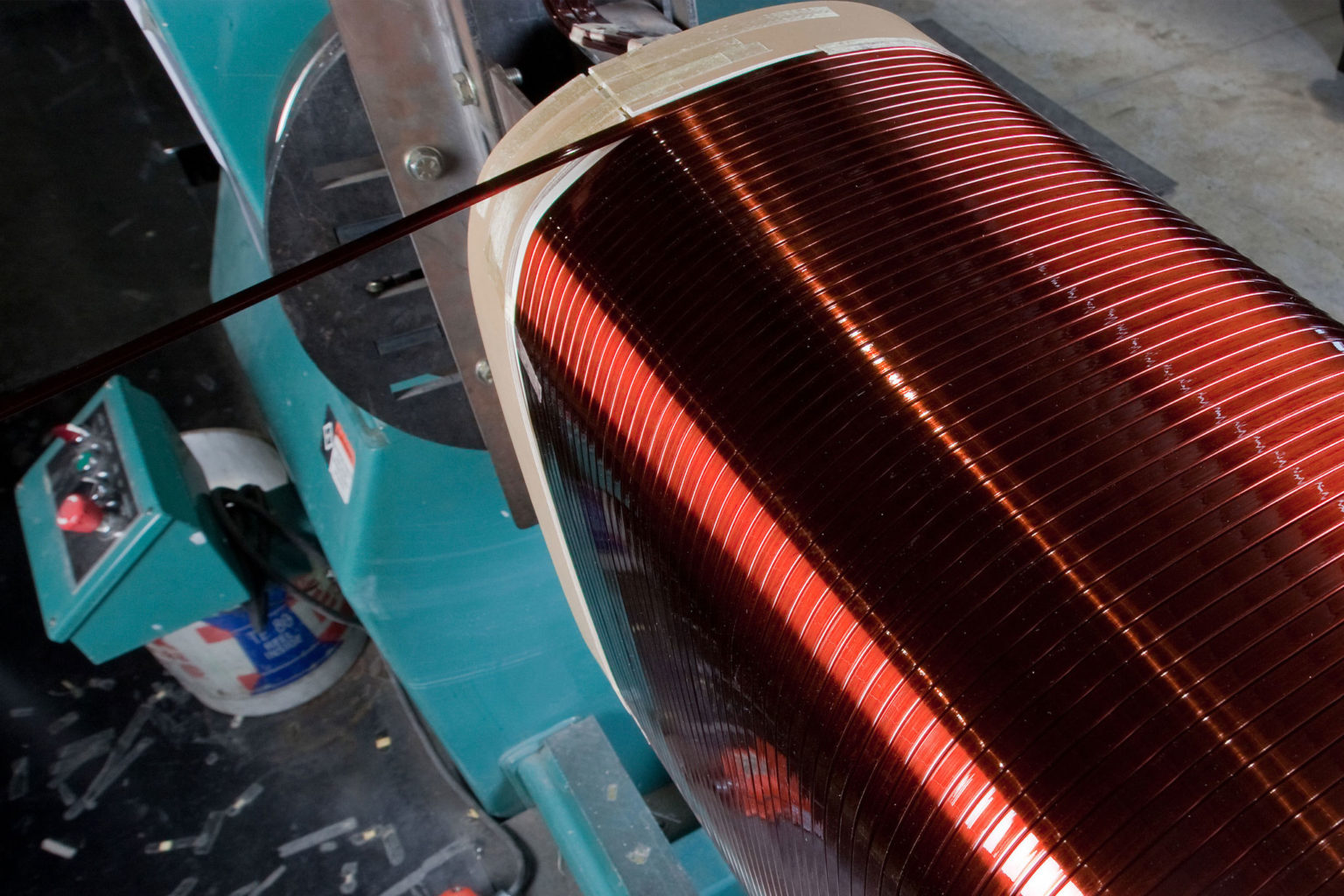

Recently, the company has sold a batch of high-conductivity rectangular and square aluminum wires overseas, which have been well received by customers. This batch of magnet wires has passed a series of tests to a very high standard, we refer to the following documents:

Standard Test Method for Resistivity of Electrical Conductor Materials

Standard Specification for Aluminum Rectangular and Square Wire for Electrical Purposes

Standard Test Methods for Tension Testing Wrought and Cast

Standard Test Methods for Chemical Analysis of Aluminum and

Comparative Characteristics: Aluminum Alloy Wrought Products

The chemical composition of this batch of magnet wire is as follows:

Aluminum, min:99.50

Boron, max :0.05

Chromium, max:0.01

Copper, max:0.05

Gallium, max:0.03

Iron, max:0.40

Manganese, max:0.01

Silicon, max :0.10

Vanadium plus titanium, max:0.02

Zinc, max:0.05

Bending tests were first carried out to obtain the mechanical properties of the magnet wire. We did not produce any signs of cracking of the bent material by cold bending 180 degrees edgewise around a mandrel of diameter 1 half the width of the bent material. So the tensile strength is very high.

For electrical properties, we have tested the following: Materials – Materials should be of uniform quality and temper, clean, bright, undamaged, smooth and free of pipes, laps, cracks,

kinks, twists, seams, damaged ends and other detrimental imperfections or defects within good business

practice.

Splices – Splices can be made in wire by electric butt welding to best commercial standards prior to final drawing

practice. Splices must not be made during final draw or in the finished wire.

Surface Cleanliness – Unless special cleaning is specified, EMPIS materials B12B20A and B12B20M1 may have slight

Loose aluminium flakes and aluminium oxide dust and coatings of EMPIS materials B12B20C and B12B20M2 may have

Light oil coating with a small amount of aluminium flakes and aluminium oxide dust.

EMPIS materials B12B20C, C9, M2 and M3 – should be able to anneal to very soft when heated to 375 °C and held

15 minutes at temperature

EMPIS Materials B12B20C9 and B12B20M3 – Only available in 0.390″ x 0.150″ dimensions.

Edge finish and profile (EMPIS materials B12B20A, C and C9 only) – should be a finished edge with rounded corners

Approximate quarter circle with radii as shown in the table below. The arc is not necessarily tangent to the plane, but

The material shall be commercially free of sharp, rough or protruding edges.

We also perform tensile testing to determine resistivity, spectrochemical and other analytical methods to provide methods for determining chemical composition; however, unless otherwise agreed by buyer and supplier, ASTM E 34 shall be used as the basis.

Because of a series of professional and reliable tests, our products have certified test certificates. In terms of packaging, it is also very satisfying to our customers that our materials should be properly sized for shipping and should be packaged in a way that is properly protected

Injured or lost in transit. Each box, crate, bale, etc., shall be clearly marked with the purchase order number, manufacturer’s name, weight, size and designation.

This business cooperation was a complete success, customers are very satisfied with our products, and we will also sell better products to you.